NIOSH recently recommended that OSHA lower hexavalent chromium airborne exposure levels below previously OSHA-endorsed levels. This recommendation has renewed the discussion on acceptable emission levels in manufacturing communities. As a result, companies are advised to review their manufacturing processes and equipment and consider implementing proactive changes to control their possible emissions.

This paper addresses some of the questions the new NIOSH recommendations have generated (and resurrected) including:

- What is hexavalent chromium?

- Where does hexavalent chromium come from?

- In what industrial processes do workers experience hexavalent chromium exposure and how might it affect the body?

- What has inspection activity been finding for the standard as it exists today?

- What are the new NIOSH recommendations?

- What types of engineering controls are possible?

Chromium shows up in predominantly three forms:

-

Trivalent Chromium, which occurs naturally as chrome ore and is also an essential nutrient for proper metabolism;

-

Metallic or Elemental Chromium, typically found in aerospace alloys; and

-

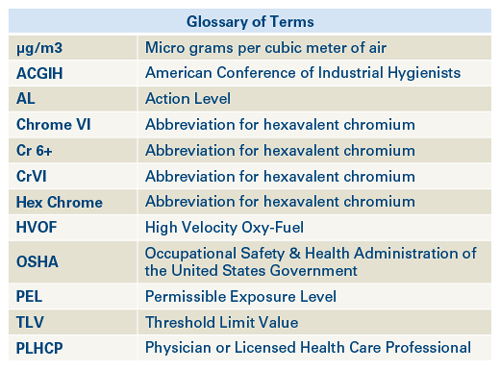

Hexavalent Chromium, typically generated by industrial processes like welding and thermal spray. Hexavalent Chromium is the most toxic form of chromium. You will see hexavalent chromium identified in different ways, including: Hex Chrome, Chrome VI, CrVI and Cr 6+.

Some of the industrial processes that produce hexavalent chromium include:

- Coatings containing chromates: dyes, paints, inks and plastics

- Chrome plating

- Blending/sanding coatings containing chromium

-

Welding of alloys containing chromium

-

Thermal Spraying, including plasma, electric arc and combustion (including HVOF)

- Metallic chromium in the feedstock may be converted to the hexavalent form.

- Hexavalent chromium may be present in a feedstock containing any form of chromium.

-

Smelting of Ferro-Chromium Ore

-

Portland cement impurities

-

Dip-tanks Anodizing and Plating lines

-

Leather tanning - Ammonium Dichromate

“The industries in which the largest numbers of workers are exposed to high concentrations of hexavalent chromium compounds include electroplating, welding and painting.” (DHHS, 2013)

Important Clarification Points: In your facility, you may be producing a dust, fume or mist that contains hexavalent chromium. It is important to realize hexavalent chromium has its own threshold limit value (TLV) and that NIOSH considers all hexavalent chromium compounds produced to be occupational carcinogens.

Remember hexavalent chromium is typically only a small percentage of the mass for any dust, fume or mist generated. Understanding the percentage of the contaminant that is actually hexavalent chromium allows for better decisions on your control strategy. It is still entirely possible that controlling a general contaminant to levels below its TLV may still allow hexavalent chromium levels to exceed the TLV for hexavalent chromium.

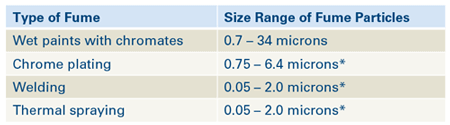

Typical particle sizes produced in the processes that potentially generate hexavalent chromium containing material may differ by process and application. For example:

*80% of total fume is in this very small size range.

If your company has any process that could be producing hexavalent chromium, your workers could be exposed through one or more of many routes.

· They could inhale hexavalent chromium through their nose and mouth from dust, fume, or mist-producing processes.

· If a medium (dust, fume, or mist) containing hexavalent chromium lands on an employee’s skin, hexavalent chromium may be absorbed through their skin.

· Or they may be exposed by ingestion (swallowing). If workers fail to use proper personal hygiene, the exposed area of clothing or skin can carry hexavalent chromium that can end up on food, tobacco and/or cosmetics and be ingested as a consequence.

Once in the body, hexavalent chromium typically targets some of a body’s organs. Respiratory tract problems can include inhalation damage to mucous membranes, perforation of septum (tissue between the nostrils of nose), and damage to the lungs. In addition there may be injury to the eyes, skin, liver and kidneys as examples. A worker exposed to hexavalent chromium may experience symptoms such as sinus irritation, nosebleeds, ulcers (stomach and nose), skin rash, chest tightness, wheezing and shortness of breath.

If a company has determined that it could potentially be producing hexavalent chromium, it is required to do the following:

-

Implement air sampling,

-

Monitor and notify employees of monitoring results,

-

Implement engineering controls,

-

Adopt respiratory protection program,

-

Demarcate work areas containing hexavalent chromium,

-

Execute an employee training program, and

-

Provide availability of OSHA regulations and company policy to employees.

The frequency of air sampling a company must do depends on the level of hexavalent chromium that was discovered in the facility. If the area tested above the PEL of 5.0 µg/m3, testing has to be done every three months. If the area is above the Action Level of 2.5 µg/m3 but below the PEL, then a company is only required to do air sampling every six months. If the area is below the action level, the company is required to take an initial baseline and then it is left up to the facility hygienists to decide on a sampling frequency. Annual sampling is a typical strategy in this case.

Monitoring of all employees is required in facilities that test above the Action Level of 2.5 µg/m3. The standard on hexavalent chromium requires medical surveillance but leaves the selection of the specific tests to the physician or other licensed health care professional (PLHCP.) This may be an on-site company nurse or the employee may need to go to his own health care provider for tests.

Some of the things that a company could do include:

- Review of health and work history,

- Physical exam, and

- Report of the outcome of the exam.

Once an exam is completed, a written summary should be provided to the employee within two weeks, and kept on file at the company by the industrial hygienist.

A review of OSHA’s website reveals little data specifically for hexavalent chromium and inspection levels. What can be observed from the data is that from 2006 to 2009, 437 manufacturing companies had personal sampling of Cr (VI), and of those companies, 65% had confirmation they had hexavalent chromium in the air, and 23% had concentrations above the PEL. Without having completed the sampling, companies would not have understood how much hexavalent chromium was in the air nor would they have been able to understand what corrective actions needed to be done.

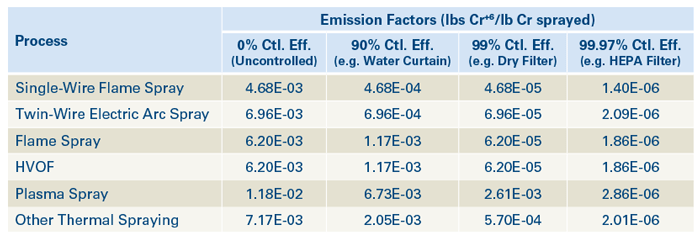

Personal sampling of air is perhaps the best method for determining the level of hexavalent chromium. In California, estimating emission levels is allowed, and the California Air Resources Board has provided help to supply companies in its state with the ability to calculate hexavalent chromium emission levels based on the idea that thermal spray processes turn 30% of all chrome sprayed by any method into hexavalent chromium. The expected emission factor summary for hexavalent chromium is:

Source: California Code of Regulations Section 93101.5

The chart above is used to calculate the annual expected emissions based on materials used and already (or to be) installed control technology. The emissions volume calculated can help determine whether the control technology being used today (or the control technology planned to be used for a new process) is adequate. There are three tiers defined on volumes and minimum efficiency control requirements:

Source: California Code of Regulations Section 93101.5

If a company calculation determines no new control collection technology needs to be installed, compliance with permitting, monitoring and recordkeeping are still required. This decision, of course, assumes everything is static in the process. If workloads or materials change, this may change the calculation and could force upgrades to the control system. Examples of how to perform the calculation are found in the California Code of Regulations.

New NIOSH Recommended airborne hexavalent chromium Exposure Levels

The Occupational Safety & Health Administration (OSHA) currently has defined two levels of hexavalent chromium exposure. The current Permissible Exposure Level (PEL) is 5 µg/m3 in an 8-hr shift from an original PEL (pre May 2010) of 52 ug/m3. This represented a decrease by a factor of 10!

The other level is called the Action Level at 2.5 µg/m3. This is the level where employers are required to take specific actions, and failure to take these actions may result in penalties.

In January of 2013, NIOSH announced a new Recommended Exposure Level (REL) of 0.2µg Cr(VI)/m3 for an 8-hour time weighted average exposure during a 40-hour workweek. NIOSH stated that the new recommendation is to prevent workplace hexavalent chromium exposure to reduce workers’ risk of lung cancer. “NIOSH also recommends that dermal exposure to Cr(VI) compounds be prevented in the workplace to reduce adverse dermal effects including skin irritation, skin ulcers, skin sensitization and allergic contact dermatitis.” (DHHS, 2013)

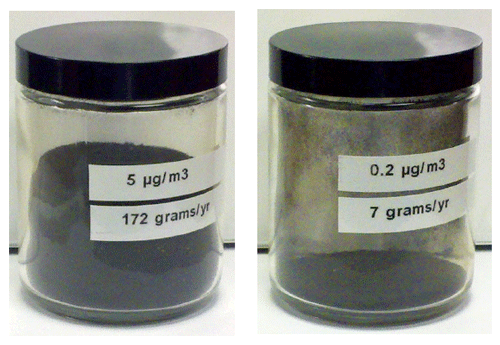

As an example of how current OSHA endorsed levels of 5 µg/m3 compare to the NIOSH recommended level of 0.2 µg/m3, look at the total amount of allowable emissions for a 10,000 CFM (17,000 CMH) system running 8 hours per day or 40 hours per week equates to 172 grams/year and 7 grams/year of fume respectively. Shown in Figure 1 are two cannisters that help illustrate this difference in fume volumes for a one year period.

Figure 1 – Comparison of fume volumes for a one-year period.

As of May 31, 2010, processes producing hexavalent chromium above the PEL of 5 µg/m3 must have engineering controls implemented. Until then, respiratory protection is mandatory until engineering controls are implemented. Please note rotation of employees to different jobs to achieve compliance is NOT permitted by OSHA.

Employees have responsibilities to protect themselves, too. They are required to use proper personal protective equipment, good housekeeping skills, engineering controls once implemented, and good personal hygiene techniques. Good personal hygiene includes not using tobacco, not applying cosmetics, not eating anything, not placing fingers in mouth or nose, and washing hands/face prior to doing any of the above activity, such as before taking a break, or at the end of their shift.

The collection system used for dust, fume, or mist control is a key factor in achieving effective control of hexavalent chromium.

As shown in the chart regarding Size Range of Fume Particles, the size of the fume particles that carry hexavalent chromium varies from 5/100 of a micron to 34 microns, with most in the very small range (sub-micron to 2 microns).

It is therefore necessary to use filter media in the collection system that can capture a full range of sizes, from sub-micron to large particulate. High efficiency filters are recommended, such as Ultra-Web® nanofiber filters from Donaldson® Torit®.

Each filter should have at least 1.5 inches of water gauge pressure drop across it to ensure performance.

A well-designed ventilation system will have sufficient capture velocities at the various hoods to help control any emissions containing hexavalent chromium. The ACGIH Industrial Ventilation Manual offers several examples, including:

-

VS-90-01 through 03 for Welding

-

VS-90-20 for Robotic Welding

-

VS-90-30 for Metal Spraying

-

VS-90-10 for Torch Cutting

-

Laser tables 250 fpm for zone (not covered)

Combined with powerful Donaldson Torit® PowerCore® TG collectors, Downflo® Oval dust collectors, Easy-Trunk® or Porta-Trunk® fume collectors, a well-designed and operated ventilation system can reduce exposure to dusts and/or fumes containing hexavalent chromium.

Ambient fume collection (sometimes termed general ventilation) is NOT recommended, as it typically only cleans 70% of the air at any given time. Ambient collection is simply not effective enough to take care of fumes potentially carrying hexavalent chromium. Capture hoods located as close to the source of generation as possible, and ducted into a well-built dust/fume collector, will ensure better confinement of the particles.

Your Donaldson Torit sales representative can help in determining which dust/fume filtration products are best suited to your ventilation system design and operation. While NIOSH experts should be trusted to provide hexavalent chromium expertise, Donaldson Torit engineers know air filters and can assist you in selecting the filter suitable for your ventilation needs.

In summary, hexavalent chromium is a regulated, toxic material that must be dealt with by implementing proper precautions. Now that NIOSH has recommended new lower – more stringent - levels to OSHA, companies are advised to be proactive in reviewing their processes. If elimination (1st choice) or substitution of materials (2nd choice) is not possible then companies should consider:

- Engineering controls where required,

- Respiratory protection if needed,

- Good housekeeping practices,

- Proper personal protective equipment, and

- Good personal hygiene practices.

American Conference of Governmental Industrial Hygienists (ACGIH). (2013). Industrial Ventilation: A Manual of Recommended Practice for Design (28th ed.). Cincinnati, OH: Kemper Woods Center.

(N.A., N.D.), “Airborne Toxic Control Measure to Reduce Emissions of Hexavalent Chromium and Nickel from Thermal Spraying”, Title 17, California Code of Regulations, Section 93101.5. Retrieved from: http://www.arb.ca.gov/coatings/thermal/emissions.pdf

(N.A., N.D.), “Hexavalent Chromium [Cr(VI)] Exposure – Industry Profile (Sector) OSHA IMIS Personal Sampling Data for Hexavalent Chromium (2006-2009)”, Retrieved from: http://www.osha.gov/SLTC/hexavalentchromium/industryprofile_sector.html

(N.A., Jan 2013), “Criteria for a Recommended Standard. Occupational Exposure to Hexavalent Chromium.” Department of Health and Human Services (DHHS), Centers for Disease Control and Prevention (CDC) & National Institute for Occupational Safety and Health. |