Fire and Explosion Mitigation

Today’s NFPA regulatory guidelines governing Fire & Explosion Protection installations are more specific and well defined than ever before. Boss Products has developed and brought to market the EcoMAXX® and EcoMAXX®/VigilEX® family of SAFETY SMART solutions to work as individual components or as seamless plantwide solution to meet this need.

We are proud to be your single source supplier for all of your fire and explosion isolation, suppression, and diversion needs.

Click Here to View All Videos - Boss Products

Click Here to Download Full Catalog - Boss Products

The installation of an explosion isolation device on all suction side ducting that transports combustible dust is an NFPA requirement. Installing a SAFETY SMART EcoMAXX® No Return Explosion Isolation Valve will protect workers and facilities from the damaging effect of a baghouse or filter explosion.

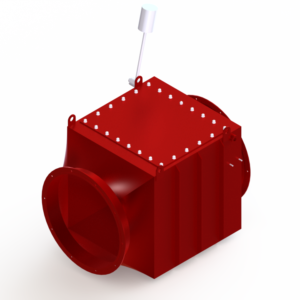

Model No. EM-NRV

No Return Valve

Standard Features

- Heavy-duty welded steel construction

- Flanged inlet and outlet with co-flanges

- Inspection/access door

- Grounding lug

- Locking mechanism

- ATEX certification – en16447

Optional Features

In addition to the standard features, all EcoMAXX® No Return Valves can be configured to include the following optional features:

- Micro-switch for system shutdown*

- Dust level sensor*

- Intrinsically safe control panel*

* Required for NFPA 69 Compliance

EcoMAXX® Float Valves are passive explosion isolation devices for use in clean air and light to medium dust loading applications. Where similar valves fail due to clogging, the SAFETY SMART EcoMAXX® Float Valve excels in today’s product flow requirements with its unique clean out technology that eliminates the concern of powder impeding closure.

Model No. EM-FV

Float Valve

ATEX Certified EN 15089 & NFPA 69 Compliant

Available in Aluminum or Mild Steel (dependent on size) and Stainless Steel 304 and 316 construction

Standard Features

- Total passive approach eliminating the costly maintenance associated with active detection or monitored systems

- Flexible use of venting approaches – eliminates the low Pred requirement of some flap and pinch style valves.

- Eliminates powder blockage considerations from product fallout with clean-out technology – monitoring of product build-up not required.

- Field flow and pressure adjustments to meet the most stringent process flow considerations.

- Single acting and double acting versions

- Flanged inlet and outlet

- Latching mechanism

- Position switches for process shutdown signaling

- Available for horizontal or vertical installation

- Certified ATEX EN 15089 & NFPA 69 Compliant

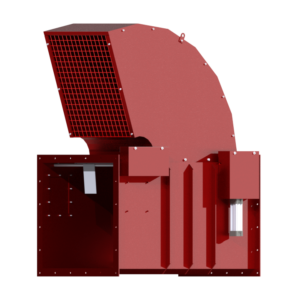

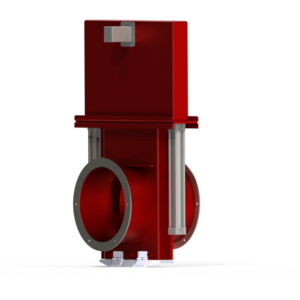

The EcoMAXX® High Speed Abort Gate is a NFPA compliant safety device for installation in baghouse & dust collector return air systems to automatically vent fire, harmful gases and burning material to atmosphere.

Model No. EM-HSAG

High Speed Abort Gate

Standard Features

- 24VDC control panel with status lights for connection to spark detection system (110VAC is available on request)

- Weather hood

- Manual rearm (sizes 8 “– 12”)

- Manual ream with pneumatic switch (sizes 18” and larger)

- Epoxy powder coated safety red finish

- Flanged inlet & outlet

- NFPA compliant with spark detection system

An EcoMAXX® High Speed Abort Gate is an essential SAFETY SMART component in any dust collection combustible dust mitigation solution.

EcoMAXX® High Speed Abort Gates are engineered with TRIPLE SECURITY.

- Activation by Spark Detection System

- Activation by Thermal Probes (Detection of a rapid temperature rise in the dust collector)

- Activation by over pressure & without electrical signal

The EcoMAXX®/VigilEX® Explosion Diverter (Flame Front Diverter) is a passive device to interrupt and divert the transmission of explosive pressure and flames in connecting pipelines and/or return air ducting. The SAFETY SMART design protects in both directions, avoids pressure piling and can be used for both fire and explosion mitigation when installed in conjunction with EcoMAXX® FireBreak Shutters and detection controls.

Model No. EV-VDIV

Explosion Diverter

Standard Features

- Passive system for interconnecting dust handling pipelines and clean air/return air protection

- Flanged inlet and outlet

- Eliminates pressure piling

- Bi-directional protection

- EV-VL Flat or EV-VD Domed explosion panel and breaking signal sensor options

- Fully compatible and can be used with EcoMAXX® FireBreak Shutters,Thermal Probe and Spark Detection & Extinguishing Systems for a fire and explosion mitigation solution.

- ATEX Certified explosion vent panels and NFPA 69 compliant – design in accordance with EN 16020 standard

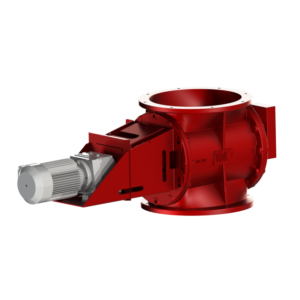

The EcoMAXX® EM-RVEX line of NFPA 69 compliant ATEX explosion tested and certified rotary valves provide effective explosion isolation for industrial filtration, pneumatic conveying and bulk handling processes. Standard, medium and heavy-duty designs with multiple rotor tip options available.

Model No. EM-RVEX

Certified Rotary Valve

All EM-RVEX Rotary Valves are ATEX Certified EN 15089 & NFPA 69 Compliant

EM-RVEX-HT series:

- Sizes: 10” (250mm), 14 ” (350mm) & 18” (450mm)

- Certified to withstand explosive pressures up to 1.7 bar (24.66 PSI)

- 8 vane rotor with Vulkollan (polyurethane) flex tips

- Cast iron housing with flanged inlet/outlet

- Direct drive motor with flexible coupling and gearbox

- Options for variable speed controller, flange gaskets, isolation box, air purge seals, special plating such as chromium or nickel, stainless steel construction and quick disassembly are available.

EM-RVEX-HTS series:

- Sizes: 10” (250mm), 14” (350mm) & 18” (450mm)

- Certified to withstand explosive pressures up to 2.5 bar (39.26 PSI)

- 8 vane rotor with options for steel or stainless steel tips

- Cast iron housing with flanged inlet/outlet

- Direct drive motor with flexible coupling and gearbox

- Options for variable speed controller, flange gaskets, isolation box, air purge seals, special plating such as chromium or nickel, stainless steel construction and quick disassembly are available.

EM-RVEX-MD Series:

- Sizes: 6” (150mm), 8” (250mm), 10” (250mm) & 12” (300mm)

- Certified to withstand explosive pressures up to 2.5 bar (39.26 PSI) / 1.7 bar (24.66 PSI) with Vulkollan tips

- Easy access to the inside of the valve

- 8 vane rotor with options for Vulkollan (polyurethane) steel or stainless steel tips

- Cast iron housing with flanged inlet/outlet

- Direct drive motor with flexible coupling and gearbox

- Shaft sealing with adjustable gland gasket

- Options for variable speed controller, flange gaskets, isolation box, air purge seals, special plating such as chromium or nickel, stainless steel construction and quick disassembly are available.

EM-RVEX-JK series:

- Sizes: 22” square as well as sizes typical to European designed dust collectors

- Certified with pressure monitoring control system

- 8 vane rotor with rubber tips

- Flanged inlet/outlet

- Direct drive motor with safety coupling and gearbox

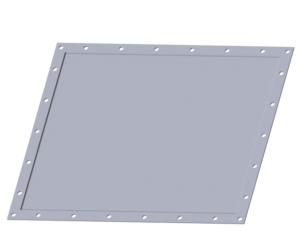

The EcoMAXX®/VigilEX® EV-VL Flat Explosion Panel is suitable for low vacuum or positive pressure applications such as bucket elevators, conveyors, silos, cyclones, and positive or low negative pressure dust collectors.

The EV-VL comes standard with an integral flange with full face gasket that covers the breaking point and ensures mechanical durability and perfect dustproof seal.

Model No. EV-VL

Flat Explosion Panel

ATEX Certified – Ex II GD, EN 14491, EN 14994, EN 14797, EN 1127.1 & NFPA 68 Compliant

Explosion vent sizing calculation services based on NFPA 68 are available free-of-charge!

17 standard stock panel sizes inventoried in Schertz, TX for quick shipment.

Standard Features

- KST max: 500 bar m/s

- 304 stainless steel construction

- -20” WG (-50 mbar) pressure resistance, 1.45 PSIG (0.1 bar) Pstat

- Integrated flange

- EPDM or Silicone gasket

- Burst sensor mounting tab

- All products in stock at traditional quantity pricing for small orders

- Positive pressure up to 50% of static burst pressure

Options

- Custom burst pressures (Pstat)

- Custom sizes and bolt patterns

- Burst sensors (magnetic, breakable, cable and mechanical)

- Intrinsic safety control box for breakable and cable burst sensor connection

- Weather cover

- Thermal insulation

- Discharge duct

- Vacuum safety grid

- 316 stainless steel construction

- FDA and high temperature gaskets

The EcoMAXX®/VigilEX® EV-VD Domed Explosion Panel is designed for vacuum and pulsating applications such as dust collectors, cyclones and pneumatic conveying systems with strong vibration.

The EV-VD comes standard with an integral flange with full face gasket that covers the breaking point and ensures mechanical durability and perfect dust proof seal.

Model No. EV-VD

Domed Explosion Panel

ATEX Certified – Ex II GD, EN 14491, EN 14994, EN 14797, EN 1127.1 & NFPA 68 Compliant

Explosion vent sizing calculation services based on NFPA 68 are available free-of-charge

16 standard stock panel sizes inventoried in Schertz, TX for quick shipment.

Standard Features:

- KST max: 500 bar m/s

- 304 stainless steel construction

- -80” WG (-200 mbar) pressure resistance, 1.45 PSIG (0.1 bar) Pstat

- Integrated flange

- EPDM or Silicone Gasket

- Burst sensor mounting tab

- All products in stock at traditional quantity pricing for small orders

Options:

- Custom burst pressures (Pstat)

- Higher vacuum resistance

- Burst sensors (magnetic, breakable, cable and mechanical)

- Intrinsic safety control box for breakable and cable burst sensor connection

- Weather cover

- Thermal insulation

- Discharge duct

- Vacuum safety grid

- 316 Stainless steel construction

- FDA and high temperature gaskets

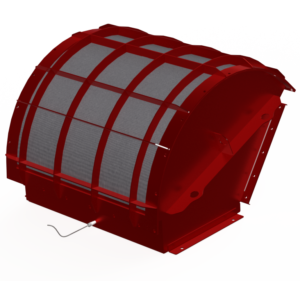

Flameless Explosion Vents are a safe and effective solution for protecting machinery and personnel located indoors. The EV-VQ provides effective low-pressure resistance and eliminates the spread of flame and glowing particles. During the beginning stage of a deflagration the interior explosion panel opens and dust (burning and non-burning) enter the flame arrestor. Flame propagation beyond the EV-VQ is prevented by energy dissipation in the arrestor, reducing the burning fuel below its ignition temperature. All dust is retained within the EV-VQ and gases from the explosion are vented through the device into atmosphere.

Model No. EV-VQ

Flameless Explosion Vents

EcoMAXX®/VigilEX® Flameless Explosion Vents

ATEX Certified – Ex II GD, Ex II 2 D, EN 16009 & NFPA 68 Compliant

Explosion vent sizing calculation services based on NFPA 68 are available free-of-charge

10 flameless vent sizes available inventoried in Schertz, TX for quick shipment.

Standard Features

- Choice of EV-VL flat panels or high pressure EV-VD domed panels

- Burst sensor supplied with flameless vent package

- All products in stock at traditional quantity pricing for small orders

- Inspection door for maintenance without requiring the removal of the flameless vent from the vessel.

- Mild steel construction with safety red finish

Options

- Dust cover bags

- Intrinsic safety control box for sensor connection

- Stainless steel construction

EcoMAXX® FireBreak Shutters are engineered to isolate fires and fire hazards in process ventilation and dust collecting applications. FireBreak Shutters are installed in a multitude of applications ranging from wood dust, metal dust, oil mist and/or any other process that has a fire hazard. Preventative (active) and reactive (passive) solutions are available.

Model No. EM-FBS

FireBreak Shutter

Available Models

- EM-FBS00G – Gravity closure with manual reset

- EM-FBS00F – Gravity closure with manual reset. Fusible link activation.

- EM-FBS00M – Gravity closure using magnetic release with a pneumatic reset.

- EM-FBS00P & EM-FBS00PH – Pneumatic closure & reset, designed for vertical and horizontal positions.

Common applications include but are not limited to:

- Secondary protection in a Spark Detection and Extinguishing System

- Detect and isolation systems without suppression

- Dust collector/vessel isolation when used with a Fire Suppression System

- Production area/work zone isolation for high-risk processes

Standard Features

- 4 models/styles available from sizes 8” to 48” diameter

- Heavy-duty welded steel construction

- Flanged inlet and outlet with co-flanges

- Self-cleaning design

- Integral gasketing for positive seal

- Epoxy powder coated safety red finish

- ATEX certified*

* Model FBS-00M is provided as non-ATEX CE listed standard. ATEX version is available upon request.

Optional Features

In addition to the standard features, all EcoMAXX® Fire Break Shutters can be configured to include the following:

- Thermal Probes for rapid temperature rise activation

- Microswitch for system shut down

- Compressed air reservoir tank

- Fire Suppression System

- Spark Detection and Extinguishing System

The EcoMAXX® Spark Detection and Extinguishing System detects sparks and glowing embers; suppressing with water spray within milliseconds of detection. The control module ensures integrated fire and explosion protection with numerous EcoMAXX® hazard sensors and mechanical protection devices. The standard control system will protect multiple zones in a single location for the ultimate protection against fire and explosions.

Model No. EM-FCS

Spark Detection

Standard Features

- Base panel capable of protecting 5 ducts with primary and secondary protection (Detect > Extinguishing > Redetect > FireBreak Isolation)

- Microprocessor with advanced software to allow for customization of all inputs, outputs, timers and operation.

- Bluetooth capable, smartphone app and modem

- Advanced optical and infrared light-sensitive spark detector

- Pulse count detection feature to adjust sensitivity for various applications and processes

- Integrates with EcoMAXX® Thermal Probes, Dust Probes, Smoke Detectors, High Speed Abort Gates, FireBreak Shutters, Fire Suppression and much more.

- FM Approved, ATEX & CE

Options

- Complete startup and commissioning service

- External Test Lamps

- Water Pressure Booster Pumps

- Thermal Probes

- Dust Probes (broken bag detectors)

- Smoke Detectors

- High Speed Abort Gates

- FireBreak Shutters

- Fire Suppression (for vessel/dust collector)

EcoMAXX® Fire Suppression Systems combine patented and FM approved FireTrace technology with the advanced EcoMAXX® Fire Control Panel, detection sensors and FireBreak Isolation Shutters. Packaged and custom solutions available with isolation for both active and passive protection. All systems are designed to suppress Class A, B & C fires. Standard suppression agents include (but not limited to): ABC Dry Chemical, CO2, and clean agents such as Novec and FM-200.

Model No. EM-FCS-SUP

Fire Suppression

As a first line of defense, the EcoMAXX® system detects potential fire events at a predetermined level. The system/process is shut down, isolation is activated and the suppressant is released.

Example Installation of an EcoMAXX® Active Dry Chemical Packaged Fire Suppression system protecting a dust collector.

Standard Features for Active Dry Chemical Packaged Fire Suppression Systems

- Modular design to protect small or large vessels

- 2-cylinder sizes available (10lb, and 20lb)

- NEMA 4/12 enclosure for indoor or outdoor installations

- EcoMAXX® EM-FCS-CU1610 FM Approved control panel

- Thermal Probes to detect a rapid temperature rise

- Ability to connect various other sensors

- Outputs for FireBreak Isolation, system/process shut down and alarm signaling

- Discharge nozzles, blow off caps and bulkhead fittings

- Manual release and charging port on enclosure door

Standard Features for Active CO2 and Clean Agent Fire Suppression Systems

- Modular design to protect small or large vessels

- Multiple cylinder sizes available

- EcoMAXX® EM-FCS-CU1610 FM Approved control panel

- Thermal Probes to detect a rapid temperature rise

- Ability to connect various other sensors

- Outputs for FireBreak Isolation, system/process shut down and alarm signaling

- Discharge nozzles blow off caps and bulkhead fittings

- Manual release and charging port on enclosure door

Standard Features for Passive Fire Suppression Systems (All Agents)

- Modular design to protect multiple vessel sizes

- Multiple cylinder sizes available

- Activation by linear detection tubing network

- Power supplies and solenoids for shut down and alarm signaling

- Discharge nozzles, blow off caps and bulkhead fittings

Options for all systems:

- Complete Start up and Commissioning Service

- Discharge Hose and Fittings

- Thermal Probes

- Dust Probes (broken bag detectors)

- Smoke Detectors

- High Speed Abort Gates

- FireBreak Shutters

EcoMAXX® Thermal Probes detect fire hazards in dust collectors and storage vessels. Independent outputs are provided to detect a rapid temperature rise, detect a temperature threshold, or both the same time. Thermal Probes can be used in conjunction with a comprehensive EcoMAXX® fire protection solution, or as a standalone product.

Model No. EM-FCS-TP

Thermal Probe

Standard Features

- Independent outputs to detects a rapid temperature rise of 41°F (5°C) in 5 seconds, temperature threshold of 176°F (80°C) or both at the same time.

- 24VDC input power

- Die cast aluminum enclosure – ATEX zone 22 rated

- Measurement range: -40° F to +302° F (-40° C to +150° C) on stylus

- Mounting kit – threaded flange adapter and fitting

- FM Approved, ATEX & CE

Options for all systems

- Spark Detection and Extinguishing System

- Fire Suppression System

- High Speed Abort Gates

- FireBreak Shutters

The EcoMAXX® Dust Probe monitors the clean air exhaust of a dust collector for leaks and filter failure. Upon detection of dust in the clean air line, the dust probe can signal an alarm, provide system shutdown, activate a High Speed Abort Gate or other process specific safety equipment. Basic and advanced models available.

Model No. EM-IMS-DP

Dust Probe

Standard Features for Model: EM-IMS-DP01

- Outputs for pre-alarm and alarm

- 24VDC input power

- Die cast aluminum enclosure – ATEX zone 22 rated – IP 65

- Electrode length is 9.84″ (250mm). Multiple probe extension options available

- Mounting kit – threaded flange adapter and fitting

- ATEX & CE

Standard Features for Model: EM-IMS-DP02

- For use for use with MM01 or MM02 (text or graphical based) microprocessor module

- 24VDC input power

- Die cast aluminum enclosure – ATEX zone 22 rated – IP 65

- Electrode length is 9.84″ (250mm) – multiple probe extension options available

- Mounting kit – threaded flange adapter and fitting

- ATEX & CE

Options for both models:

- Spark Detection and Extinguishing System

- Fire Suppression System

- High Speed Abort Gates

About Dust Collector Services

From Routine Inspections to Regular Maintenance, Baghouse Services are Our Business!

With more than 30 years' experience, our personalized service includes baghouse inspection reports that detail current conditions in each unit and locate potential problems before they elevate to emergency status. Acting preventively, rather than reactively, your overall maintenance costs remain low. We're good at troubleshooting. It's what we do best. Our highly experienced staff evaluates and solves problems fast, putting you back in service with minimal downtime. From routine inspections to a new Baghouse, we offer a complete range of Services. Our field engineering experts can update your equipment to the latest technology available, improving performance and reducing the cost of operating your Baghouse.

Call Today 800-282-3878 so that we can help you with you next dust collection project, service or maintenance on all types of dust, mist and fume collection equipment.

Certifications

Let Dust Collector Services helps with all your OSHA and NFPA requirements.