Dust collectors are an integral part of many plants’ combustible dust compliance strategies. As such, dust collection companies have had to remain active in supplying dust collectors to support a customer’s combustible dust control strategy by interfacing with the customer and its experts on fire and explosion protection equipment and strategies.

This content is intended to increase the reader’s understanding of typical combustible dust management strategies and some of the components involved. It will cover:

- What is currently going on in the industry?

- Are there new rules I need to know about?

- What does this mean to me?

- What does this mean to my customers?

- Why should dust collectors be part of my strategy decision?

WHAT IS CURRENTLY GOING ON IN THE INDUSTRY?

The U.S. Occupational Safety and Health Administration (OSHA) has issued a National Emphasis Program and continues to communicate with most industries on the hazards of combustible dust. Since passing the combustible dust program (CPL 03-00-008) in March 2008, the agency's focused effort is targeted at reducing combustible dust risks in industrial plant settings.

OSHA has increased its regulatory attention due to three catastrophic dust explosions that resulted in 14 fatalities. The events at West Pharmaceutical, CTA Acoustics and Hayes Lemmerz resulted in the US Chemical Safety and Hazard Investigation Board (CSB) publishing a report stating dust fires and explosions in the last 25 years had resulted in 119 fatalities and over 700 injuries.

Since March of 2008, OSHA has been issuing publications on combustible dust and doing inspections specifically targeting facilities it knows deal with combustible dusts. As a result, OSHA has done over 800 inspections and issued almost 4,000 violations with fines and penalties in excess of $1.0 million dollars. Items frequently cited include:

- Housekeeping

- Hazard communications

- Use of personal protective equipment

- Electrical Installation

- General Duty Clause (5a1)

Some of the common problems OSHA sees include:

- Missing or ineffective dust control leading to housekeeping issues

- Dust collectors indoors, rather than outside as OSHA expects to see if the collectors filter combustible dusts

- No isolation on inlets and/or outlets to prevent the propagation of an deflagration to other process equipment

- Explosion vents

- Dust collectors with no vents that are filtering combustible dusts

- Dust collectors with vents that are venting to an unsafe area

We are told that when an OSHA inspector walks into a facility, housekeeping is one of the first things he/she evaluates. If a high percentage of surfaces are covered by combustible dust, OSHA inspectors take notice. The measurement that serves as a type of benchmark in the industry is 1/32 of an inch deep of dust.

The second thing OSHA evaluates is record keeping. Inspectors typically look for:

- Process Safety Assessments on all processes in the plant

- Published operating procedures for all processes in the plant

- Existence of inspection records

- Combustibility data on all dusts produced in the plant. Specifically, they look at Kst deflagration index or rate of pressure rise, Pmax (maximum pressure), Minimum Ignition Energy for static electricity holding dusts and Minimum Ignition Temperature.

In addition to the above items, OSHA may also evaluate ducting and piping. Inspectors may look at bonding and grounding. They may also look for ignition control efforts.

It is important to note these examples of commonly investigated items are not all inclusive when it comes to reviews of facilities. When OSHA visits facilities, the most commonly referenced standards are the NFPA standards. Know that these standards go through regular revision cycles and are updated every 4-5 years. OSHA is also in development of its own combustible dust standard, but its publication date is unknown at this time.

Often when it comes to understanding these issues and standards, customers ask for guidance in who to consult so they can know what to do to be in compliance. The first key player a customer should seek out is an Authority Having Jurisdiction (AHJ). By definition in NFPA 68, an “AHJ is an organization, office or individual responsible for enforcing the requirements of a code or standard, or for approving equipment, materials, an installation or a procedure.” A few examples of AHJs include but are not limited to: insurance inspection departments, rating bureaus, Fire Marshalls and certainly OSHA inspectors.

Since each AHJ may have a specific set of codes he or she references, you may need to have general knowledge of more than one standard or code. As a process owner, you are responsible for the selection of your combustible material management strategy. You also need to assure your process and facility comply with all applicable federal, state, and local codes and standards. Many standards and codes may influence your decisions on dust control, including the local, state, and federal regulations. Knowing the codes that apply to your facility is critical, and you should always research the code requirements in your area. Just to reiterate, a few commonly referenced standards for combustible dust risk management strategies include those issued by: National Fire Protection Association (NFPA), the International Mechanical Code, the International Fire Code, Factory Mutual Property Loss, and OSHA (federal). Since these standards are often cited by OSHA, and have been adopted as code in many areas of the country, they may be a good starting point for consideration in developing your combustible dust management strategy. For more free information visit www.nfpa.org.

ARE THERE NEW RULES I NEED TO KNOW ABOUT?

We are often asked if these standards or rules are new? They are not; the NFPA standards have been available for review for years, but it was only recently that NFPA documents became “standards” rather than “guidelines.” Now with NFPA standards and the combustible dust NEP, there is increased focus and attention on combustible dust. What this mean for facility owners is:

- They must have a strategy for combustible dust in their facilities and be prepared to discuss it,

- They must have a familiarity with the standards and codes in their industry and area,

- They should expect a review of current and expansion projects, and

- They are well advised to be proactive in mitigating combustible dust issues.

In order to understand what rules apply, know this:

- When the AHJ adopts a standard, it becomes the rule or the code.

- OSHA’s Combustible Dust NEP is often the first reference point, but other codes could be in place and will also need to be reviewed.

- Other standards often adopted include but are not limited to:

- Additional NFPA standards

- International Code Council Codes

- Factory Mutual Data Sheets

- Corporate Practices or Standards

WHAT DOES THIS MEAN TO ME?

WHAT DOES IT MEAN TO MY CUSTOMERS?

For a facility owner the question may arise, “When might I expect an inspection”? OSHA’s NEP focuses first on key industries with known combustible dusts in their processes, but it will consider combustible dust issues on any report or claim if they have reason or cause when visiting the facility. When OSHA does an inspection, it may use current standards - not the version in effect when the equipment was installed. If OSHA finds anything in direct violation with the currently adopted rules and regulations or current NFPA Standards, it can, and will likely issue citations.

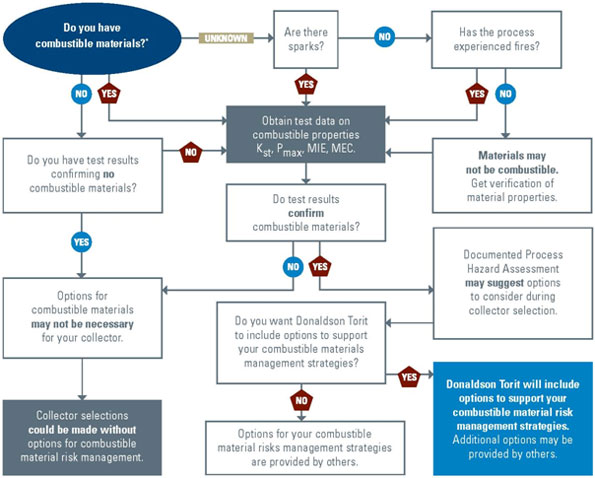

Because of all of this, customers wonder where to start when thinking about their combustible dust strategies. A dust collector representative can review your operational challenges to help you better understand how to integrate dust collection into your combustible dust management strategy. The following considerations may help you decide how you want the dust collector representative to support your combustible dust management strategy:

Many manufacturing processes create very small particles of dust, which may become airborne where they then settle on surfaces and in crevices throughout the plant. Eventually these particles not only create a housekeeping issue, but if the particles are combustible, they can represent a potentially explosive dust cloud if disturbed.

It is essential for plant leaders to understand the risks of combustible dust and ensure they manage combustible dusts in their facilities. Dust collector representatives can help to support your combustible dust control strategy by interfacing with you and your experts on fire and explosion protection equipment and solutions. Combustible dusts generally present both fire and explosion risks so it may help to consider the management of these risks separately.

WHY DUST COLLECTORS

SHOULD BE PART OF YOUR STRATEGY DECISION

Many process requirements make elimination of combustible dust, mist, or fume impractical. However, it may still be very possible to manage the dispersion of dust within your plant by using an appropriate and effective industrial ventilation system including dust collection. A well designed, maintained, and operated industrial ventilation system including good hoods, proper duct sizes, and properly selected collection equipment can provide effective dust control and can therefore help manage the presence of dispersed dust. This not only reduces housekeeping frequency and expense, but also may help you reduce the risk of dust explosions in your facility, particularly the destructive secondary explosions, by helping reduce the presence of dispersed fuel in your facility.

Fire Triangle

|

Fire risk management strategies traditionally focus on the control or elimination of one of the three key elements necessary for a fire — often represented by the fire triangle. Managing one or more of the elements in the triangle can decrease the fire risk. |

Explosion Pentagon

|

Explosion risk management strategies consider a slightly expanded set of elements often represented as an explosion pentagon. In addition to the key elements from the fire triangle — fuel, heat, and oxygen, the explosion pentagon includes two additional elements necessary for an explosion: Dispersion of Dust and Confinement of Dust. As with fire management strategies, the management or removal of one or more of the elements in the explosion pentagon can reduce the explosion risk. While many explosion management strategies focus on controlling the same elements in the fire triangle, explosion risk management strategies that focus on the dispersion of dust, or the containment of dust alone, may require a separate strategy to address any remaining fire risks. |

Combustible dust remains a widely discussed topic and management of dust using filtration technology will have a role in many risk management strategies. To see how dust collectors can work help with your combustible dust risk management strategy, call us for more detailed information.

|